Learning Objectives:

Producing a product made of multiple components

requires significant coordination to ensure that component parts are available

when they are required for production. This segment examines how MRP can

accomplish this coordination.

Contents:

Translating an Aggregate Plan into a Production and

Ordering Schedule

Aggregate Plan (3-12 months

ahead)

Master Production Schedule (1-3

months)

Material Requirements Plan (0-3 months)

- A detailed plan that states how many END ITEMS

(the final product sold to the customer) will be available for sale or

distribution during specific periods

- Short time frame: 1-3 months

Purposes of the Master Production Schedule:

- to

set due dates for the availability of end items

- to

provide information regarding resources and materials required to support

the aggregate plan

- as

an input to Materials Requirements Planning, which will set specific

production schedules for parts and components used in end items

What the Master Production Schedule is NOT:

- a

sales forecast (MPS summarizes production to meet sales forecasts)

- a

manufacturing schedule (MPS tells when end items are available for sale,

but not when the end items or their component parts will be manufactured)

Inputs To Mps

- Market

requirements

- Production

Plan from Aggregate Planning

- Resources

available

Constraints

- Quantities

of individual items must equal aggregate quantities from the Production

Plan

- Demand

which must be met

� Capacity available

Output

An MPS showing end items available every month (or

period) that is feasible with respect to demand and capacity.

At this point we know when we need units available

so we can plan when to produce or order using MRP.

A

computerized system for managing dependent-demand inventory, scheduling

replenishment orders, and meeting demand for end items as given in the Master

Production Schedule.

Two basic characteristics of MRP:

- MRP

derives demand for components, subassemblies, materials, etc., from demand

for and production schedules of parent items.

- MRP

offsets replenishment orders (purchase orders or production schedules)

relative to the date when replenishment is needed.

|

Information

Needed for MRP

|

Information

Obtained from MRP

|

|

|

MRP Inputs

1. Master Production

Schedule

- Product Structure

- Inventory Levels

Lot Sizing Choices in MRP

Lot sizing:

Determining

the lot size (order quantity or production quantity) of an item

Static lot sizing rule:

- A

decision rule that orders the same quantity each time an order is placed.

- Tend

to generate higher average on-hand inventory because they create inventory

remnants.

- Can

provide extra safety stock.

Dynamic lot sizing rule:

- A

decision rule that changes the order quantity with each order, typically

so that each order is just large enough to prevent shortages over a specified

time period.

- Tend

to cause instability by tying lot-size to gross requirements.

- Lower-level

components may not be able to respond sufficiently fast to changes in

requirements.

Static Lot-sizing Rules

1. Fixed order quantity (FOQ)

- Order

(or produce) a fixed quantity, or a multiple of that fixed quantity.

2. Economic Order Quantity (EOQ)

- Order

(or produce) the economic order quantity, plus any additional items needed

to replenish safety stock if it has fallen below its desired level.

- Yields

minimum total setup/ordering plus holding costs.

- Assumes

relatively constant demand.

Dynamic Lot-sizing Rules

1. Lot-for-Lot (L4L)

- Order

(or produce) exactly the quantity required in each period to satisfy gross

requirements and to maintain safety stock at its required level.

- Simple

to use, and agrees with Just-In-Time philosophy of ordering/producing only

when required.

- Lot

size can be modified easily for purchase discounts or restrictions, scrap

allowances, process constraints, etc.

- Minimizes

on-hand inventory, but maximizes number of orders placed (so can be

expensive if setup/ordering costs are significant).

2. Periodic Order Quantity (POQ)

- Order/produce

a quantity equal to the gross requirements for P periods minus any

items in on-hand inventory plus any additional items

needed to replenish safety stock if it has fallen below its desired level.

- Restores

safety stock and covers exactly P periods of gross requirements.

- Reduces

on-hand inventory by attempting to match the quantity ordered to the

quantity required.

Completing MRP Tables

Objective:

The

purpose of MRP is to schedule orders for end

items and the components of those end

items. We wish to determine when to release orders and how

much to order.

Step 1

Begin with the end items. Complete one table at a

time.

- Schedule

the gross requirements, GR.

- Enter

records for any scheduled receipts, SR.

- Consider

GR, SR and inventory, I, to determine timing and size of orders we will

plan to receive, PR. These are orders which we must receive to meet demand.

PRt = It-1 + SRt -

GRt - It

- Use

the lead time to schedule the planned order releases, POR, so that the

orders are received when they are needed.

Time of POR = Time of PR - L

- A

POR for an end item in week t becomes a GR in week t for every component part

of the end item.

Step 2

Schedule the components. If a component occurs at

more than one level it is scheduled at the deepest level so that you will know

all demand for parents of the component before you try to schedule the

component.

Level 1 components:

The POR's for end items are scheduled as GR's for

level 1 components. Any spare parts orders are scheduled as GR's also.

- Complete

the table as discussed in step 1.

Repeat the process for all components.

For each component the gross requirements come from

planned order releases for all direct parents of the component and from any

orders for spare parts.

The final result will be planned orders (quantity

and timing) for end products and all of their component which must be made in

order to meet demand.

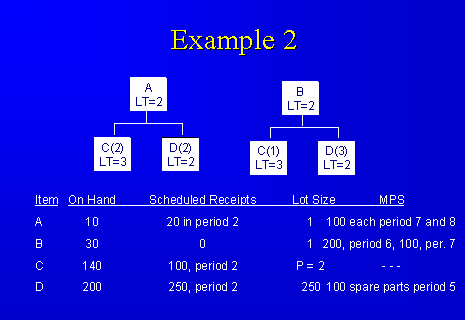

Example 2

Favourable environments for MRP:

- batch

manufacturing environment

- stable

demand

- limited

number of products

- large

number of bill-of-materials levels

- large

lot sizes

Some conditions which are less favourable for MRP

Process-focused environments:

- many

customized products

- small

production volumes

- small

number of bill-of-materials levels

Just-In-Time environments:

- small

batch sizes

- demand

pulls parts and components through the system

Closed-loop MRP:

MRP

system that provides feedback to other stages of the production plan, such as

the aggregate production plan, capacity plan, and Master Production Schedule.

Manufacturing Resource Planning (MRP II):

A

planning system that uses all outputs of a MRP system to integrate production,

marketing, and financial plans.

Distribution Resource Planning (DRP):

A

time-phased stock replenishment technique for distribution networks based on

MRP procedures and logic.

Industry Week - View selected industry related

articles in the Industry Week magazine by clicking on the magazines or by

searching for a topic.

ITEM:

|

Week

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Gross Requirements

|

|

|

|

|

|

|

|

|

|

Scheduled Receipts

|

|

|

|

|

|

|

|

|

|

Projected on hand

|

|

|

|

|

|

|

|

|

|

|

Planned Receipts

|

|

|

|

|

|

|

|

|

|

Planned

order releases

|

|

|

|

|

|

|

|

|

Tidak ada komentar:

Posting Komentar